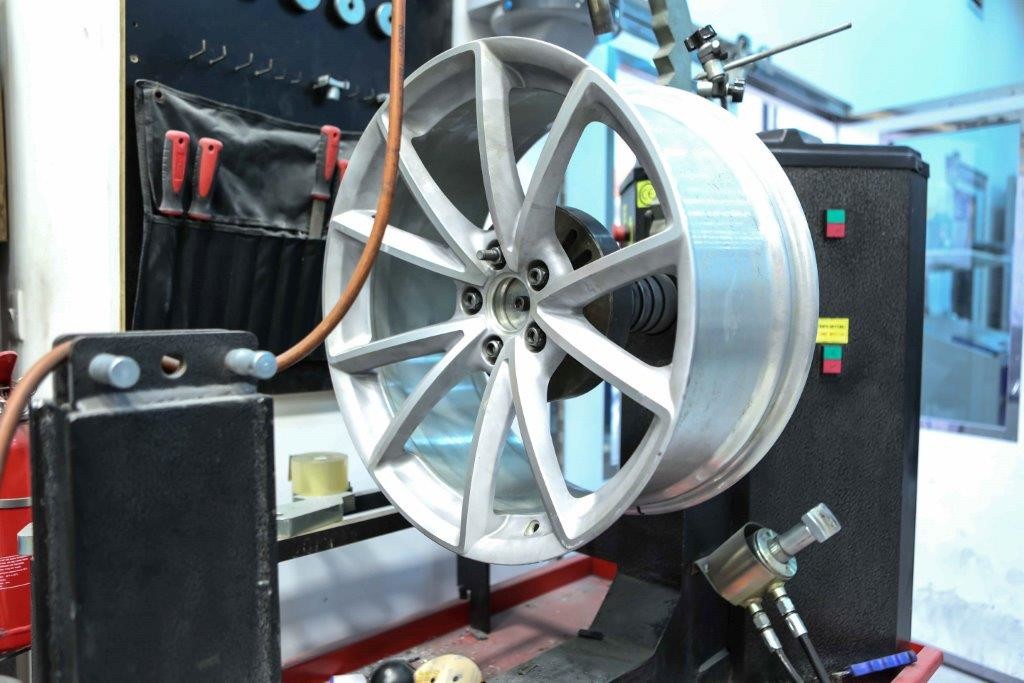

Don’t be alarmed by these photographs, even though they look like we’ve abandoned alloys to rot in an alleyway! These are actually alloys which are being prepared for diamond cutting, so they’re guaranteed to get the best treatment in the business.

Don’t be alarmed by these photographs, even though they look like we’ve abandoned alloys to rot in an alleyway! These are actually alloys which are being prepared for diamond cutting, so they’re guaranteed to get the best treatment in the business.

These wheels, which are from a Triumph Stag, have been chemically stripped to remove every single trace of previous paint, dirt, brake dust and any other corrosive substance that might have attached itself to the alloys during their life on the road.

Chemical stripping, like aqua blasting, is a process we use to ensure that the wheels are a completely blank canvass before we go onto rebuild them. This process is something you should look for from any company who repairs your alloys – it may take longer, but it’s the only way to ensure that all the damage, and anything that might cause further damage such as corrosion, is completely gone. Companies who simply

Chemical stripping, like aqua blasting, is a process we use to ensure that the wheels are a completely blank canvass before we go onto rebuild them. This process is something you should look for from any company who repairs your alloys – it may take longer, but it’s the only way to ensure that all the damage, and anything that might cause further damage such as corrosion, is completely gone. Companies who simply

patch up your alloys might give you a quick service, but you’ll end up having to take them back to the repair shop before you know it.

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

Once the stripping process is complete the alloys will be inspected, powder coated and then diamond cut for a sublime finish. This owner may well decide to update the aesthetic of his wheels and go for a different paint finish, or perhaps some coloured inserts – the possibilities are endless!

Follow

Follow

only be carried out by our trained technicians who have been repairing alloys for decades.

only be carried out by our trained technicians who have been repairing alloys for decades.