Did you know that we offer a 4-wheel discount if you have all 4 wheels refurbished at the same time? Why do we do this? Well, because we want to offer our customers a great deal and ensure you leave our West London workshop with 4 wheels that all match and look pristine. By having all 4 wheels done at the same time, you can not only save money but also ensure the paint finish is an exact match, in addition it will ensure their durability and wear are even.

Did you know that we offer a 4-wheel discount if you have all 4 wheels refurbished at the same time? Why do we do this? Well, because we want to offer our customers a great deal and ensure you leave our West London workshop with 4 wheels that all match and look pristine. By having all 4 wheels done at the same time, you can not only save money but also ensure the paint finish is an exact match, in addition it will ensure their durability and wear are even.

A refurbishment is an opportunity for you to get your alloy wheels looking in tip top condition and to get a fresh new look. We offer 2 specialist processes, diamond cutting and powder coating, which allows you to either re-fresh your original look and eradicate any kerbing damage or go for a new colour and finish. Why not try a gloss or matt finish for your alloy wheels for example.

To prolong the life of you alloys, and give a unique look, we also recommend adding Alloygators, which are protective rim bands for the outside rim of your alloys to protect them from kerbing damage which can easily happen when parking next to high kerbs for example. These can be fitted at the same time as your refurbishment.

To prolong the life of you alloys, and give a unique look, we also recommend adding Alloygators, which are protective rim bands for the outside rim of your alloys to protect them from kerbing damage which can easily happen when parking next to high kerbs for example. These can be fitted at the same time as your refurbishment.

To get a quick quote, simply call us on 0208 845 7788 or email us direct.

Follow

Follow

Did you know that

Did you know that  company or courier service, that wants to keep their alloy wheels in great condition, can rely on our trade service. Not only do we have a collection and delivery service but our rates are very competitive and we offer a speedy and reliable service.

company or courier service, that wants to keep their alloy wheels in great condition, can rely on our trade service. Not only do we have a collection and delivery service but our rates are very competitive and we offer a speedy and reliable service. We’ve got some great top tips to help ensure your tyres last for as long as possible.

We’ve got some great top tips to help ensure your tyres last for as long as possible. Take these sporty alloys from a Lotus as an example, you can clearly see how the new, completely smooth and shiny powder coating highlights the beautifully complex structure of the alloy and makes it look as good as new.

Take these sporty alloys from a Lotus as an example, you can clearly see how the new, completely smooth and shiny powder coating highlights the beautifully complex structure of the alloy and makes it look as good as new.

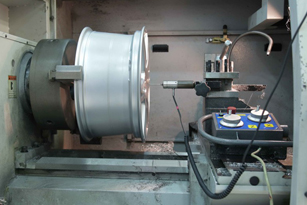

The Diamond Cutting process is extremely precise; a finish which cannot be done by hand. The Diamond Cutting machine uses laser technology to remove damage you can’t see by eye. Once the data has been processed by the machine, the Diamond Cutting starts by slowly and gradually coming closer and closer to the alloy to cut off an incredibly thin layer of the alloy. It then moves back and goes ahead and repeats the procedure to ensure no damage is missed.

The Diamond Cutting process is extremely precise; a finish which cannot be done by hand. The Diamond Cutting machine uses laser technology to remove damage you can’t see by eye. Once the data has been processed by the machine, the Diamond Cutting starts by slowly and gradually coming closer and closer to the alloy to cut off an incredibly thin layer of the alloy. It then moves back and goes ahead and repeats the procedure to ensure no damage is missed. Laser technology helps the machine to be as accurate as possible by scanning the whole alloy before any movement in the machine pinpointing the exact locations of the damage.

Laser technology helps the machine to be as accurate as possible by scanning the whole alloy before any movement in the machine pinpointing the exact locations of the damage. With potholes increasing day by day, and limited resources from councils to fix them quickly, most motorists encounter bumping over potholes on a daily basis. This is more than just a motoring annoyance. Driving over a pothole, especially at speed, can cause damage to your alloy wheels. Such damage might include denting or cracking your alloys which can cause loss of pressure and potentially cause your car to fail its MOT.

With potholes increasing day by day, and limited resources from councils to fix them quickly, most motorists encounter bumping over potholes on a daily basis. This is more than just a motoring annoyance. Driving over a pothole, especially at speed, can cause damage to your alloy wheels. Such damage might include denting or cracking your alloys which can cause loss of pressure and potentially cause your car to fail its MOT. To replace damaged alloy wheels can also be costly, so you should think about having your alloy wheels repaired at a specialist alloy wheel repair center like Diamond Alloys. In our

To replace damaged alloy wheels can also be costly, so you should think about having your alloy wheels repaired at a specialist alloy wheel repair center like Diamond Alloys. In our  At

At  We know that owners of quality vehicles like a Jaguar want a quality

We know that owners of quality vehicles like a Jaguar want a quality  These Jaguar alloy wheels pictured above had some kerb damage that required our technicians to first sand and file the alloy back into shape. They could only do this, however, after the alloys had been thoroughly cleaned with our AquaBlast machine – something that ensures we can offer the best possible repair rather than simply covering over break dust and other damaging elements.

These Jaguar alloy wheels pictured above had some kerb damage that required our technicians to first sand and file the alloy back into shape. They could only do this, however, after the alloys had been thoroughly cleaned with our AquaBlast machine – something that ensures we can offer the best possible repair rather than simply covering over break dust and other damaging elements. The overall result from powder coating is simply stunning, and we would urge you to consider it if your alloy wheels are due for a refurb. The great thing about it is that the powder comes in a huge variety of colours, so it’s a great excuse to change your look if you feel that your car is getting a bit stale!

The overall result from powder coating is simply stunning, and we would urge you to consider it if your alloy wheels are due for a refurb. The great thing about it is that the powder comes in a huge variety of colours, so it’s a great excuse to change your look if you feel that your car is getting a bit stale! At our west

At our west  The Diamond Cut is a special cutting process which removes a thin layer of metal so the alloy can get back to its original look; it is extremely precise and cannot be done by hand.

The Diamond Cut is a special cutting process which removes a thin layer of metal so the alloy can get back to its original look; it is extremely precise and cannot be done by hand. For alloy wheel trade accounts, we can also deliver and pickup alloy wheels. If you decide to choose our collection and delivery service, we will handle your alloys with care. If you decide you want to drop them off, we can cater for that too.

For alloy wheel trade accounts, we can also deliver and pickup alloy wheels. If you decide to choose our collection and delivery service, we will handle your alloys with care. If you decide you want to drop them off, we can cater for that too. If you are looking for the best finish for your alloy wheels, then we believe a

If you are looking for the best finish for your alloy wheels, then we believe a